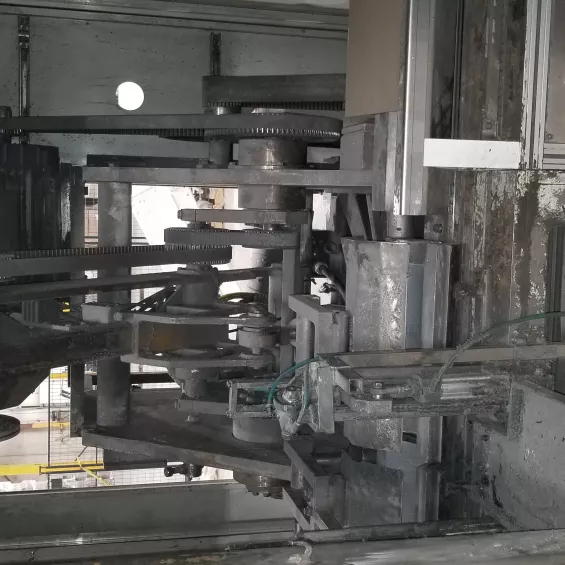

Cleaning machinery using dry ice blasting in Trenton, Ontario. This was the most effective method for this type of machinery as dry ice is non conductive and will not damage electrical components.

Industrial Machinery Maintenance and CleaningIndustrial machinery requires maintenance, regardless of its purpose. In addition to repairs and calibrations, equipment needs to be cleaned periodically.

Depending on the purpose of your factory, plant, or other industrial facility, your equipment may require regular cleaning or it may not come into contact with many foreign materials - either way, there is no way to completely prevent the inevitable buildup of dirt, dust, and grime in the machines you rely on to keep your facility running smoothly.

Not as Easy as It SeemsFor facilities with custom equipment, or machinery with complex moving parts and electronic components, cleaning may not be a simple task.

There are many factors to consider, such as protecting your equipment from damage and the environmental or safety hazards some cleaning methods may entail. Harsh chemicals and fumes can linger, harming productivity and the planet.

Abrasive methods such as sandblasting can compromise more sensitive machinery.

Electronics can be irreversibly damaged by cleaning solutions.

This industrial facility in Trenton uses machinery which requires a gentle and non-conductive cleaning method.

Quick, Safe and EffectiveOur team was able to leave the equipment perfectly clean without risking any damage or chemical residue, with dry ice blasting performed by skilled professionals.

Don’t let maintenance tasks in your industrial facility become a source of stress and expense - call the experts at Subzero Blasting for effective and safe machinery cleaning today.