Dry ice blasting is an advanced and effective cleaning method increasingly adopted by industries requiring precision and care, such as pharmaceuticals.

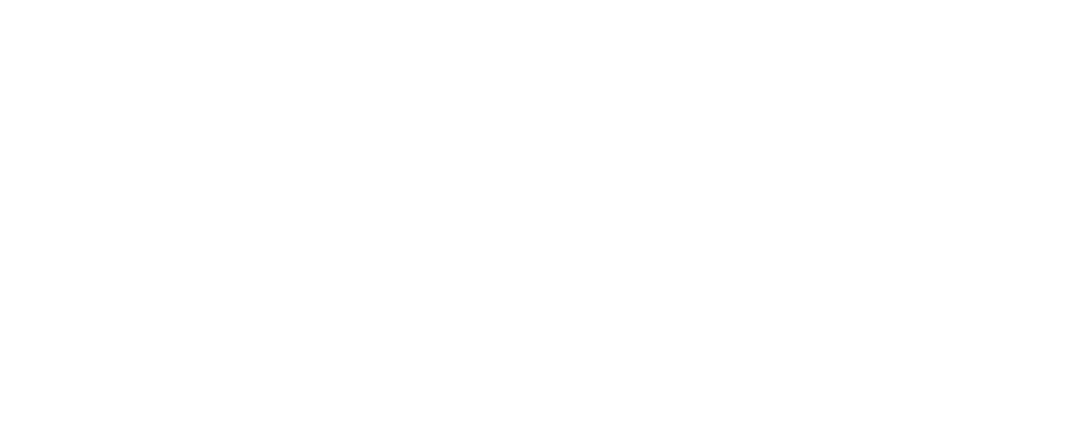

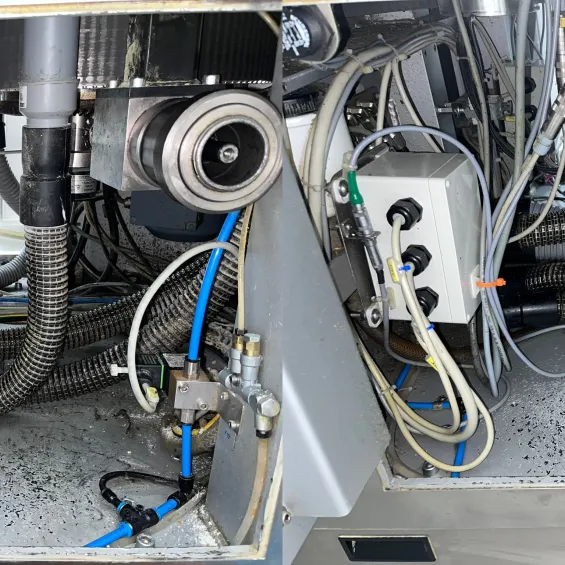

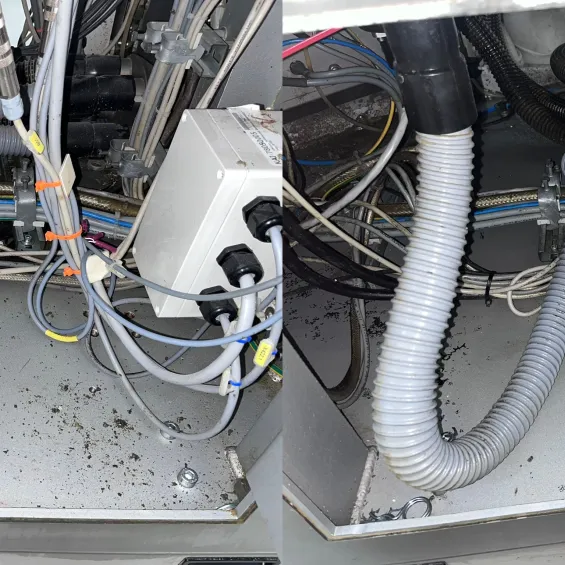

This Whitby pharmaceutical company, known for its stringent standards in product safety and cleanliness, significantly benefited from dry ice blasting for its electronic equipment.

Dry ice blasting involves using compressed air to propel dry ice pellets at high speeds.

These pellets, made of solid carbon dioxide (CO2), sublimate upon impact, transitioning directly from a solid to a gas.

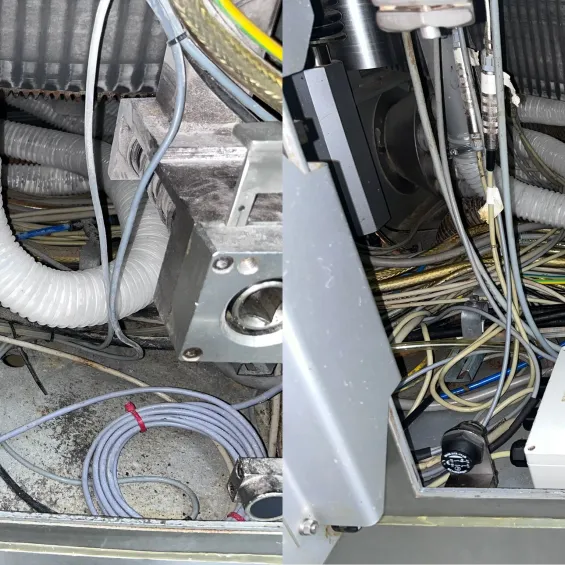

This unique property means no secondary waste is produced, unlike other cleaning methods that might leave residues or moisture.

This was particularly advantageous, ensuring that sensitive electronic components remained undamaged and contamination-free.

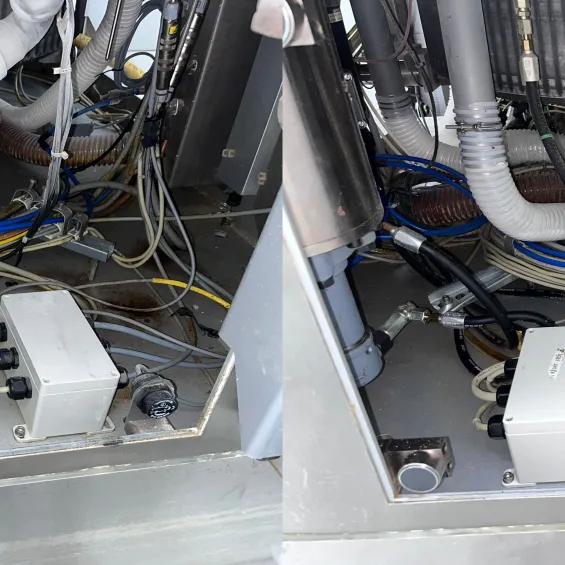

Electronics used in pharmaceutical manufacturing, such as control panels, circuit boards, and sensors, require regular cleaning to maintain optimal performance and avoid malfunction.

Traditional cleaning methods, such as water or chemical solvents, can pose risks of corrosion, short circuits, and residue build-up.

Dry ice blasting, however, mitigates these risks by being non-abrasive, non-conductive, and residue-free.

Moreover, dry ice blasting is an environmentally friendly option.

The CO2 used is often sourced from recycled industrial processes, making it a sustainable choice. Implementing this method aligns with this company's commitment to environmental responsibility and sustainability.

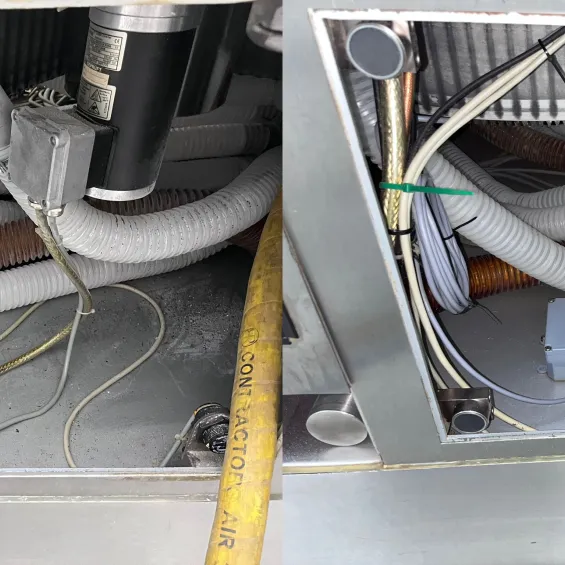

Incorporating dry ice blasting into the maintenance routine ensures that our client can maintain its high standards of cleanliness and operational efficiency.

This method not only extends the lifespan of electronic equipment but also supports compliance with industry regulations and quality control standards.