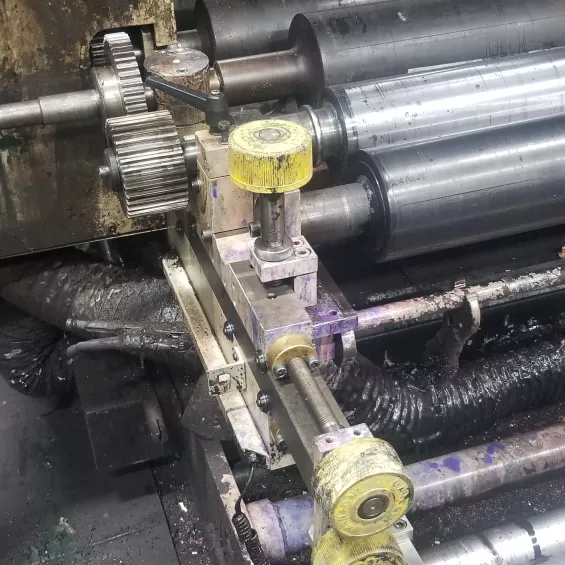

This printing company in Woodbridge had a lot of dried up ink on their printing press causing the mechanical components not to work as efficiently.

When a printing press begins to get built up ink in and around its surfaces, the mechanical components cannot work as efficiently.

If it is not dealt with, the printing press slowly depletes in efficiency. As you can see from the photos, this printing press in Woodbridge was a case as such.

Dry Ice Blasting was used as a cleaning method in order to clear up the parts of built up ink and restore the printing press’ efficiency.

Why Dry Ice is the Best Method of Cleaning a Printing PressDry ice blasting was the perfect match to remove all this ink. Why?

- no mess

- no entrapment in moving mechanical parts

- non conductive

- time efficient

Since printing presses emit so much ink, over time there is a build-up of ink in the crevices of the machine. Ink dries over time and becomes harder to clean the longer time passes. Foreign build-up forces the printing press to work harder and diminishes the machine’s structural integrity.

Dry ice blasting was the best method for removal in the case of this printing press for a handful of reasons. The technique requires little mess apart from the medium that’s being removed.

It’s a non-conductive method and requires no use of harsh chemicals.

Opposed to many other print press cleaning methods, it’s also incredibly time efficient.

Dry ice blasting left this printing press clean of any initial build-up and did not acquire any entrapment in moving mechanical parts. As a result, the printing company saved future costs in having to replace the machine, and additional hours due to inefficient printing.

Printing Press Cleaning in OntarioDo you have a printing press in need of cleaning? Perhaps you have another piece of machinery that’s slowing down in efficiency due to built up residue?

Call SubZero Blasting today for your printing press cleaning needs.