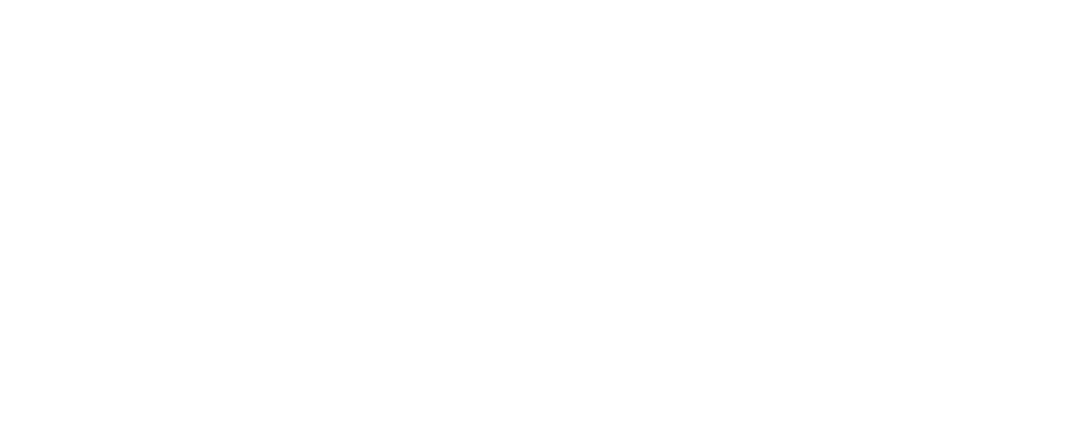

Print presses gather buildup and coatings over time. Ink, paper lint, dust, and grease can cause misalignment and registration issues, so regular deep cleaning of the print press is a must.

Avoid DowntimeThis can seem like a daunting task, and you may be concerned about the downtime or potential damage to equipment from being disassembled and painstakingly cleaned.

Certain chemicals or abrasives might be unsuitable for the smaller components of your press, and other parts (we’re looking at you, ink trays) can be particularly resistant to solvents.

Luckily Subzero’s dry ice blasting can blast away all of these concerns, like we did for this print press in Hamilton, Ontario.

Dry Ice Blast Cleaning For Printing PressesDry ice blasting leaves no residue or secondary waste behind, so this client’s press was ready to use after a quick wipedown of any non-painted parts.

Dry ice is also non-abrasive, so is safe for even the most fragile and finely-tuned components.

The best part? Dry ice blasting can be performed in place, without the need to remove rollers or disassemble other parts.

Minimize downtime, minimize risk to your equipment, and maximize the short time you dedicate to print press cleaning.

Instead of dreading cleanings for your print press, choose dry ice blasting for stunning results like these, and choose Subzero for the very best dry ice blasting professionals.