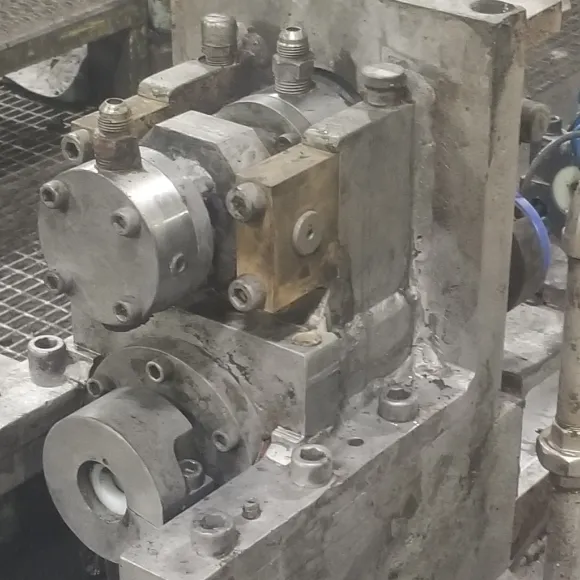

This manufacturing plant in Cobourg had years of buildup on their machinery that needed removing.

Grease and grime completely covered the machine and prior to blasting services the machine had only been hand scraped, resulting in only a 25% of the cleanliness.

How to Remove Grease Buildup with Dry Ice BlastingDry ice was the blasting method chosen for this project. This meant that there was no secondary waste, no excess water or moisture, and most importantly, no damage to the machine.

With manufacturing machines such as this one, blasting around delicate parts can often be difficult or damaging without the right tools.

Dry ice blasting gives the proper control while also being gentle enough to smaller areas.

By using dry ice blasting and giving this machine new life, the company can now repaint it and prevent it from future damage.

More About Dry Ice BlastingThe added benefits of using dry ice blasting, or pressurized carbon dioxide, means there is no secondary waste created.

Dry ice blasting carries zero harsh chemicals preventing potential damage to blasted machinery and company employees.

Most importantly, it is also time efficient and cost effective.

Dry Ice Blasting can also clean more than just machinery such as this one. It can also be used to clean:

- food processing equipment

- electrical equipment

- electrical cabinets

- pulp and paper equipment

- motors/engines

SubZero Blasting offers industrial cleaning services in Toronto and the GTA.

Save you and your company time, money and hassle and contact us directly for a quote today.