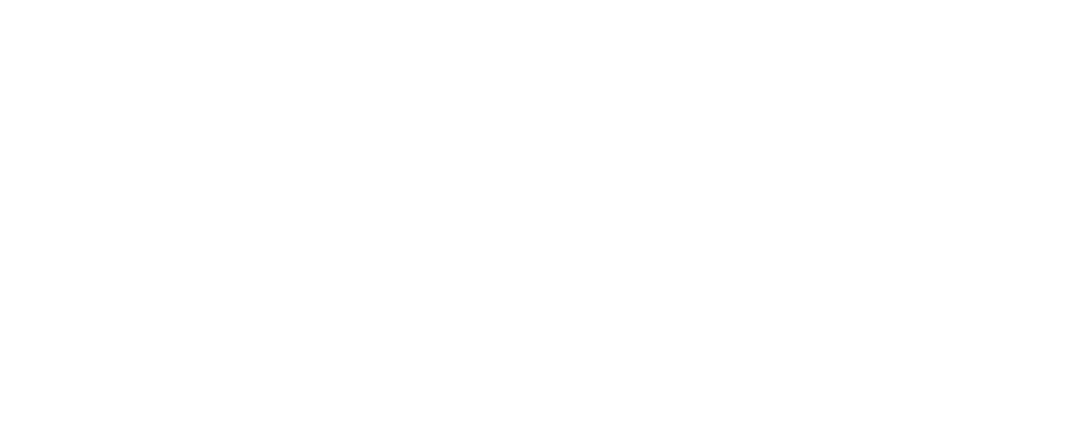

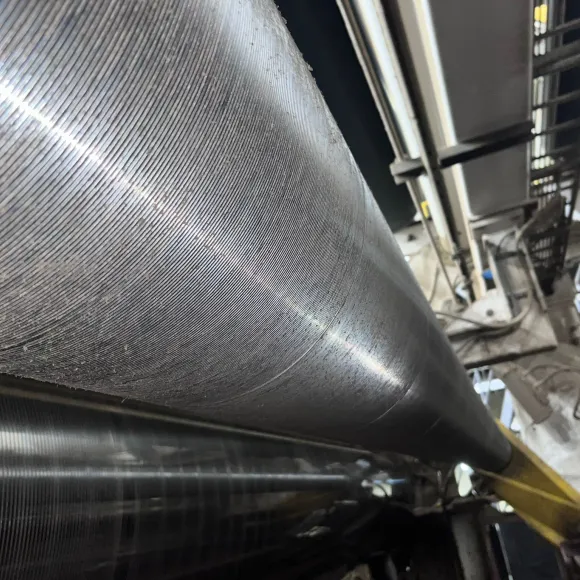

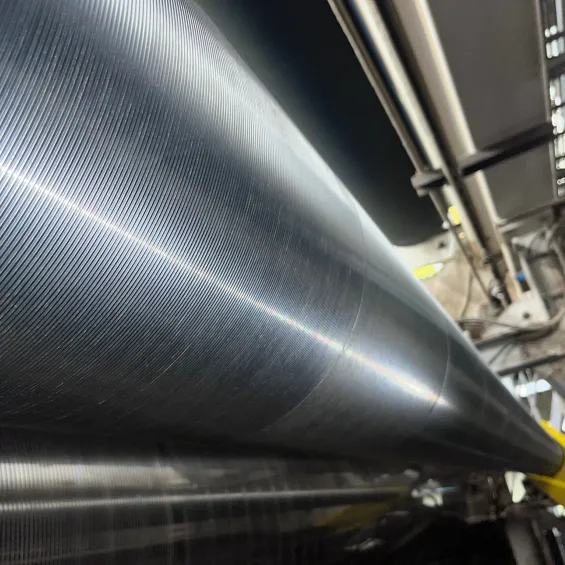

Maintaining efficient operations in large-scale facilities like Atlantic Packaging in Whitby demands innovative solutions. One critical component of their equipment is the massive stainless-steel roller, essential for seamless production. Over time, these rollers accumulate stubborn contaminants that hinder performance and lead to costly downtime.

Enter dry ice blasting—an eco-friendly cleaning method that restores equipment without abrasive wear or chemical residue. Using high-velocity dry ice pellets, this technique removes grime, adhesives, and other buildups from the roller’s surface. The result? A clean, smooth roller that operates at peak performance.

Dry ice blasting offers several advantages for industries like packaging. Traditional cleaning methods often involve disassembly, harsh chemicals, or abrasive scrubbing, all of which take time and can damage sensitive components. In contrast, dry ice blasting can be performed in place, minimizing interruptions and keeping production schedules on track. Additionally, it’s a non-abrasive process, ensuring the roller’s surface remains intact while achieving a superior clean.

For Atlantic Packaging, adopting dry ice blasting translates to increased efficiency, reduced maintenance costs, and fewer production halts. The method is not only effective but also environmentally responsible, aligning with the company’s commitment to sustainable practices.

By keeping equipment in optimal condition, dry ice blasting helps Atlantic Packaging maintain its competitive edge, delivering high-quality products with minimal downtime. Whether in packaging, manufacturing, or other industries, this cleaning innovation continues to prove its value.

Looking for reliable equipment cleaning solutions? Discover how dry ice blasting can enhance your operations today!